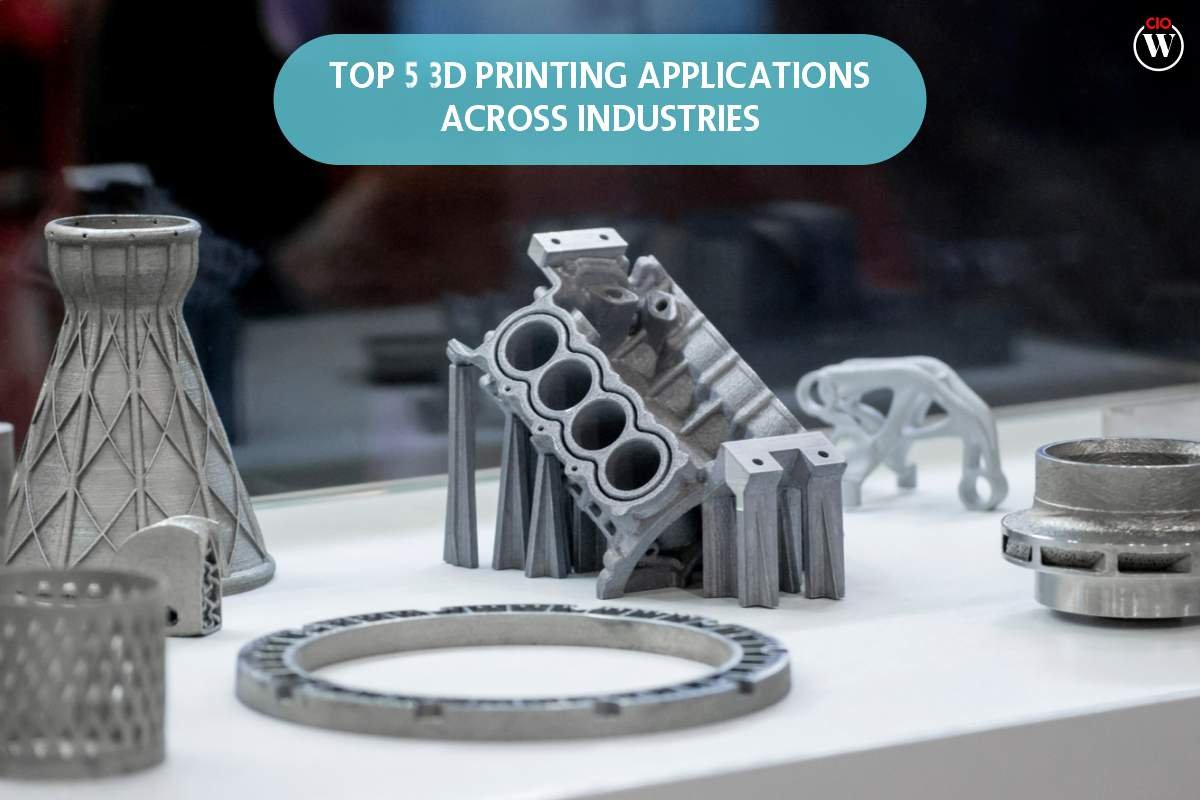

While the technology behind 3D Printing Applications has been around for decades, its popularity and practical applications have skyrocketed in the last few years. There is a steady stream of new uses for 3D printing, but the ones discussed below have seen a recent surge in interest.

3D printing’s current popularity stems in large part from the fact that it is a flexible technology with several practical uses. When it first became available, 3D printing was expensive. The cost of 3D printing models and supplies was high. Recent years have seen a decrease in the price of 3D printing equipment and the materials used in them, making its widespread industrial and educational uses more affordable.

Here are the Top 5 3D Printing Applications Across Industries;

1. HEALTHCARE

Medical 3D printing has come a long way in the previous several years. Bioprinting, in which cells and growth chemicals are mixed to form tissue-like structures that mimic their natural counterparts, is only one example. Other examples include prostheses and other medical equipment.

Prosthetics made using 3D Printing Applications demonstrate the technology’s adaptability. Producing customized prostheses is a time-consuming and costly process. Prosthetics made from precise measurements may now be created and produced for a fraction of the traditional cost, thanks to the advent of 3D Printing Applications. Kids who needed a prosthesis had to sit tight for a while to be sure they wouldn’t outgrow it.

They may now get a brand new prosthesis every few months thanks to 3D Printing Applications. When traditional prostheses are not available, as they often are in developing nations, patients there may now turn to 3D printed alternatives.

Medical 3D Printing Applications is also utilized to create metal orthopedic implants. The porous surfaces made possible by 3D printing make it possible for the patient’s own bones to grow into the implant, facilitating a more natural and seamless osseointegration.

A titanium pelvic implant was successfully placed in one patient, while a titanium lower jaw was implanted in another. An accident involving a biker resulted in severe facial injuries, and the patient’s face was reconstructed using 3D printed components.

The ability to 3D Printing Applications prosthetic organs thanks to advances in bioprinting is a boon not only to patients suffering from organ failure but also to the patients’ loved ones and the healthcare system as a whole.

Cost-effective and ethical, 3D printed tissues have been produced for pharmaceutical research to aid in identifying adverse effects of pharmaceuticals and verifying safe doses.

Binder Jetting, a kind of 3D Printing Applications, may be used to create pills. The method results in very porous pills, which are ideal for treating disorders like epilepsy because they may contain large doses in a single tablet that dissolve rapidly and are readily digested.

2. CONSTRUCTION

Buildings and construction components may now be made using 3D printing, one of several available technologies.

Powder bonding (polymer bond, reactive bond, sintering), additive welding, and extrusion of various materials (concrete/cement, wax, foam, and polymers) are all employed in building through 3D Printing Applications. The building industry is only one of many potential beneficiaries of 3D printing’s versatility.

More complicated designs can be built with greater precision and speed, while building costs are reduced, more functions can be integrated, and less material is wasted thanks to advances in technology.

In 2017, Yaroslavl, Russia saw the completion of its first apartment building. The walls, covering a total of 298.5 square meters, were printed at a shop and erected on site before the roof was finished and the inside was decorated (3213 sq ft). Design, construction permission, registration, and the connecting of all engineering systems are only few of the milestones that the project sets a new standard for. The house was not constructed for show; rather, a typical American family now makes their home there.

Since the 1990s, researchers have been working to perfect concrete 3D Printing Applications as a quicker and cheaper alternative to traditional construction methods. Printing concrete foundations and walls on-site is now possible with large-scale 3D printers. Modular concrete components may be printed and then assembled on the construction site.

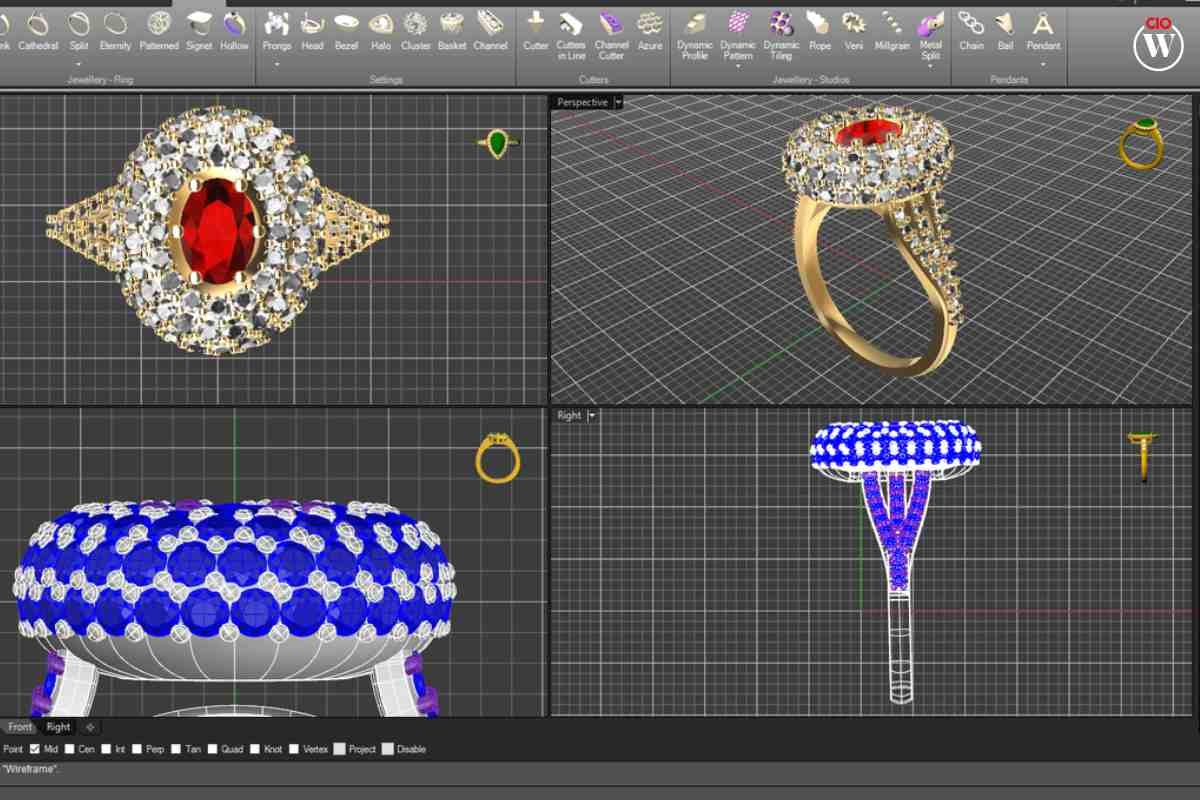

3 ART AND JEWELRY

The use of 3D printing in the creation of artwork and jewelry has been an unexpected development. By using 3D printers, jewelers may try out new, innovative ideas that would have been impossible before. Using 3D printing materials like PLA (polylactic acid filament), gold, or platinum, it is possible to produce one-of-a-kind or personalized jewelry items for a fraction of the usual cost.

Globally, artists have found new motivation in the advent of 3D Printing Applications. Especially with metal 3D printing, artists can now make stunningly detailed works.

Banksy, the secretive and renowned British graffiti artist, is only one of many artists whose works have been brought from 2D to 3D via powder binding 3D printing.

Olivier van Herpt, a Dutch artist, uses 3D Printing Applications to make ceramic vases. Danny van Ryswyk, a Dutchman, uses 3D printing to create creepy sculptures that are evocative of Tim Burton’s cinematic characters. Using just the sound waves of human speech, digital artist Gilles Azzaro turns the inaudible into the visible.

The Prado Museum has finished a show including 3D-rendered works by famous painters. The goal was to provide a tactile experience of otherwise inaccessible works of art for the sight handicapped.

These are just a few examples of how 3D printing technology have already changed the world in many fields, including science, engineering, medical, the arts, and, of course, education.

4. PROTOTYPING AND MANUFACTURING

First introduced as a tool to speed up the prototype process, 3D printing has now expanded into many other areas. Producing a single mold for a conventional injection-molded prototype might take weeks and cost hundreds of thousands of dollars. That’s not a workable approach if you want to make incremental improvements to the design.

As opposed to the weeks or months it would take using conventional manufacturing methods, a prototype may now be made in a matter of hours using 3D printing technology. Two examples of industrial sectors now capitalizing on 3D printing’s advantages are the car and aerospace industries.

When producing in big quantities, the most economical method is the standard one. 3D printing, also known as “additive manufacturing” within the manufacturing industry, is excellent for scenarios in which a product will not be mass manufactured since technology enables the low-cost, on-demand fabrication of individual units.

In a similar line, developments in RP technology have led to the creation of materials and methods like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) that are appropriate for the production of the final version of a product, as opposed to only the prototype. Rapid manufacturing describes this process.

Companies are increasingly offering cloud-based additive manufacturing services, allowing customers to produce parts and things remotely without the need for a 3D printer.

5. EDUCATION

Lessons in 3D printing are being taught in more classrooms all the time. The ability to make prototypes without the high cost of specialized equipment is one of the main advantages of 3D printing in the classroom. Students have hands-on experience with 3D printing technology as they create and take home their own designs.

The ability to print three-dimensional models from digital files fills a gap between the virtual and the real worlds.

In recent years, 3D Printing Applications have become commonplace in educational institutions and public spaces like libraries. Students at universities may make use of 3D printers for assignments and research. Certification programs in the uses of 3D printing are provided by companies like MakerBot, which may be taken by both teachers and students.

As a result of the ease with which students may create working prototypes using 3D printing technology and the abundance of open-source hardware designs, this technology is also changing the way we teach STEM subjects in the classroom.

The many uses of 3D Printing Applications in the fields of design, engineering, and architecture are investigated as a means by which students gain knowledge in this area. It allows them to examine museum objects like fossils and historical relics without risking harm to the originals. They can see topographical maps from a whole new, three-dimensional angle.