In the fast-paced world of modern logistics, efficiency is the key to success, and handheld devices for warehouses play a pivotal role in achieving this goal. These compact, portable gadgets have become indispensable tools for warehouse managers and workers alike, streamlining operations, improving accuracy, and enhancing overall productivity. In this article, we will explore 15 of the most efficient handheld devices that are transforming the landscape of warehouse management.

Here are some handheld devices for warehouses:

1. Barcode Scanners

The backbone of warehouse efficiency, barcode scanners are essentially handheld devices for warehouses. These devices enable quick and accurate tracking of inventory, reducing errors and saving valuable time. With the ability to scan barcodes on products, shelves, and pallets, warehouse staff can easily update inventory records and maintain real-time visibility.

2. RFID Readers

Radio-frequency identification (RFID) technology has revolutionized warehouse management by providing a contactless and swift means of tracking and managing inventory. RFID readers, as handheld devices for warehouses, allow users to read RFID tags from a distance, facilitating faster and more accurate inventory tracking compared to traditional methods.

3. Handheld Computers

Equipped with robust operating systems and powerful processors, handheld computers are versatile devices that combine the functionalities of a computer with the convenience of portability. Warehouse staff can use these devices for a range of tasks, including inventory management, order processing, and communication, making them an invaluable asset in a fast-paced warehouse environment.

4. Mobile Printers

Efficient labeling is crucial in warehouses for proper organization and tracking. Mobile printers, as handheld devices, enable on-the-go printing of labels and receipts. Workers can generate labels for products, shelves, and shipping packages, ensuring that all items are correctly identified and sorted within the warehouse.

5. Smartphones with Warehouse Apps

Smartphones have become ubiquitous, and with the advent of warehouse-specific applications, they have seamlessly integrated into warehouse operations. These handheld devices for warehouses can run specialized apps that assist in inventory management, order processing, and communication, providing a cost-effective and user-friendly solution for warehouse staff.

6. Voice Picking Devices

Voice-picking technology has emerged as a game-changer in warehouse operations. These handheld devices, often in the form of headsets or wearables, allow workers to receive instructions and confirm tasks through voice commands. This hands-free approach significantly improves efficiency, as workers can navigate the warehouse and pick orders without the need to refer to paper lists or handheld devices.

7. Wearable Scanners

For tasks that require both hands, wearable scanners are a practical solution. These handheld devices, worn as gloves or attached to clothing, allow workers to scan barcodes effortlessly while handling products or materials. Wearable scanners enhance mobility and streamline processes in busy warehouse environments.

8. Augmented Reality Glasses

Augmented reality (AR) glasses have made their mark in warehouses by providing workers with a visual overlay of information. These handheld devices for warehouses display relevant data, such as product details or order instructions, directly in the worker’s field of vision. This not only improves accuracy but also reduces the need for workers to constantly refer to paper documents or handheld devices.

9. Temperature and Humidity Sensors

In warehouses that store perishable goods or sensitive materials, monitoring environmental conditions is crucial. Handheld devices equipped with temperature and humidity sensors enable workers to assess the storage conditions in real-time, helping prevent spoilage and maintain the quality of goods.

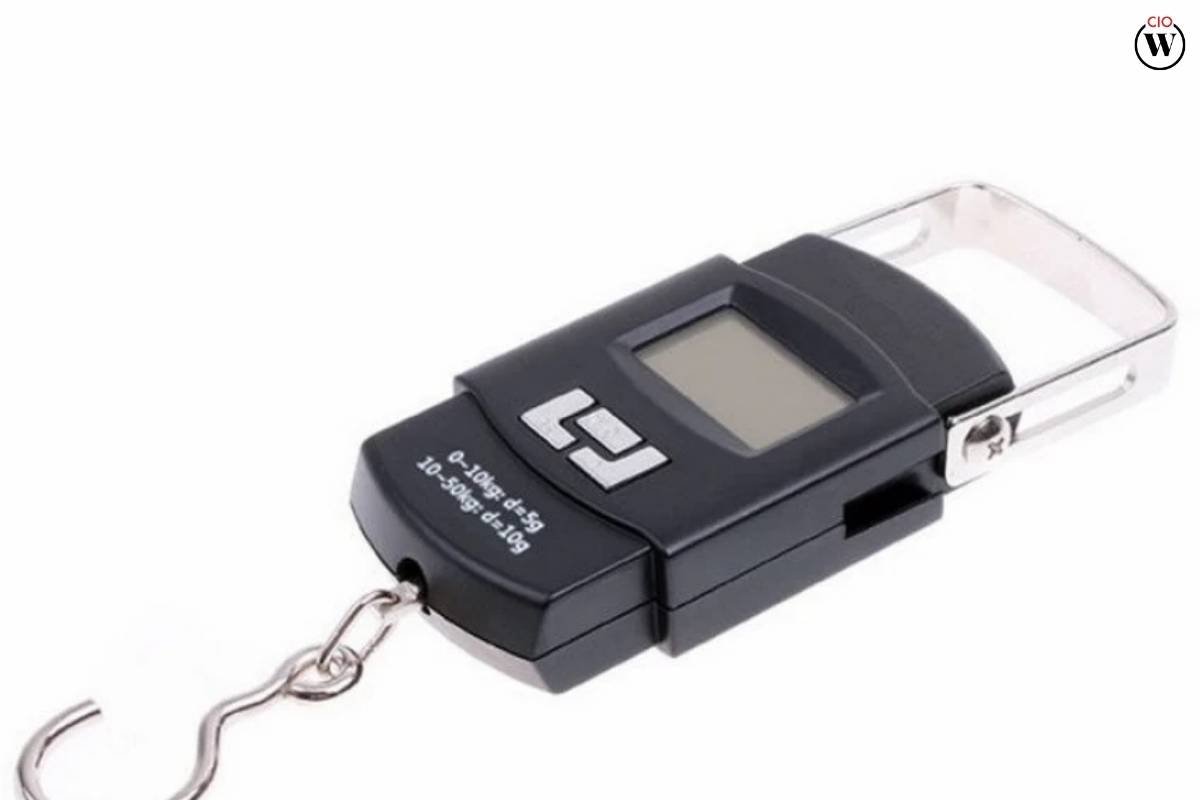

10. Handheld Weighing Devices

Accurate weighing is vital for shipping and inventory management. Handheld weighing devices allow workers to quickly and precisely measure the weight of packages or products, ensuring compliance with shipping regulations and preventing discrepancies in inventory records.

12. GPS-enabled Handheld Devices

For large warehouses or distribution centers, navigating the expansive space efficiently is a challenge. GPS-enabled handheld devices provide real-time location data, helping workers locate specific items, optimize routes, and streamline the overall workflow. These devices are particularly beneficial for minimizing the time spent searching for products in large storage facilities.

13. Mobile Barcode Printers

Mobile barcode printers are handheld devices that combine the functionality of a barcode printer with the convenience of portability. Workers can print barcode labels on the spot, ensuring accurate and up-to-date labeling for products and inventory. This eliminates the need for workers to return to a centralized printing station, saving time and improving overall efficiency.

14. Handheld Inspection Cameras

For quality control and inspection purposes, handheld inspection cameras have proven invaluable in warehouses. These devices allow workers to capture high-resolution images or videos of products, enabling detailed inspection for defects or damages. With this technology, warehouse staff can quickly identify issues and take appropriate action to maintain product quality.

15. Handheld Gas Detectors

In warehouses that handle hazardous materials, ensuring a safe working environment is paramount. Handheld gas detectors serve as a crucial safety tool, allowing workers to monitor the air for potentially harmful gases. Equipping warehouse staff with these handheld devices enhances safety protocols and ensures a secure workplace.

16. Handheld Maintenance Tools

To keep warehouse operations running smoothly, maintenance tasks must be performed promptly. Handheld maintenance tools, such as diagnostic devices or portable repair kits, empower workers to address equipment issues on the spot. This proactive approach minimizes downtime and contributes to the overall efficiency of warehouse operations.

Conclusion

In the dynamic world of warehouse management, the role of handheld devices cannot be overstated. From barcode scanners to augmented reality glasses, these efficient gadgets have become indispensable tools for enhancing productivity, accuracy, and safety in warehouses. As technology continues to advance, the evolution of handheld devices for warehouses will undoubtedly contribute to even greater efficiency and innovation in the logistics industry. Embracing these tools can propel warehouses into a new era of streamlined operations and heightened success.