When it comes to direct-to-garment (DTG) printing, the type and quality of inks used often determine the quality of the output. DTG printing has gained significant popularity recently due to its versatility and ability to create detailed designs with vibrant colours on various textile materials. In this guest post, we will explore why using high-quality inks is crucial for mastering the art of DTG printing. By understanding the importance of quality inks, printers can deliver exceptional results and satisfy customers’ demands.

Why Quality Inks Matter

1. Vibrant Colors and Accurate Reproduction

When one has buy inks for DTG printer, some things must be kept in mind. High-quality DTG inks allow for accurate colour reproduction, which is vital when printing complex designs that require precise hues. Inferior inks may result in dull or faded colours, detracting from the overall visual impact of the design. On the other hand, using premium-grade inks ensures vivid and vibrant colours that truly bring a design to life.

2. Increased Durability and Wash Fastness

When it comes to garment decorations, durability is crucial. Customers want their printed designs to remain intact even after multiple washes. This is where the importance of quality DTG inks becomes evident. Superior-grade inks are specifically formulated to adhere well to fabric fibres, ensuring long-lasting prints that resist fading or cracking even after several wash cycles.

3. Enhanced Print details

Quality matters when it comes to capturing intricate design details accurately through DTG printing. High-quality ink formulation facilitates impeccable print resolution, enabling printers to reproduce even the finest lines and gradients with exceptional precision. The result? Remarkably detailed prints that showcase finesse, whether it’s text-based designs or complex photographic images.

Choosing the Right Ink

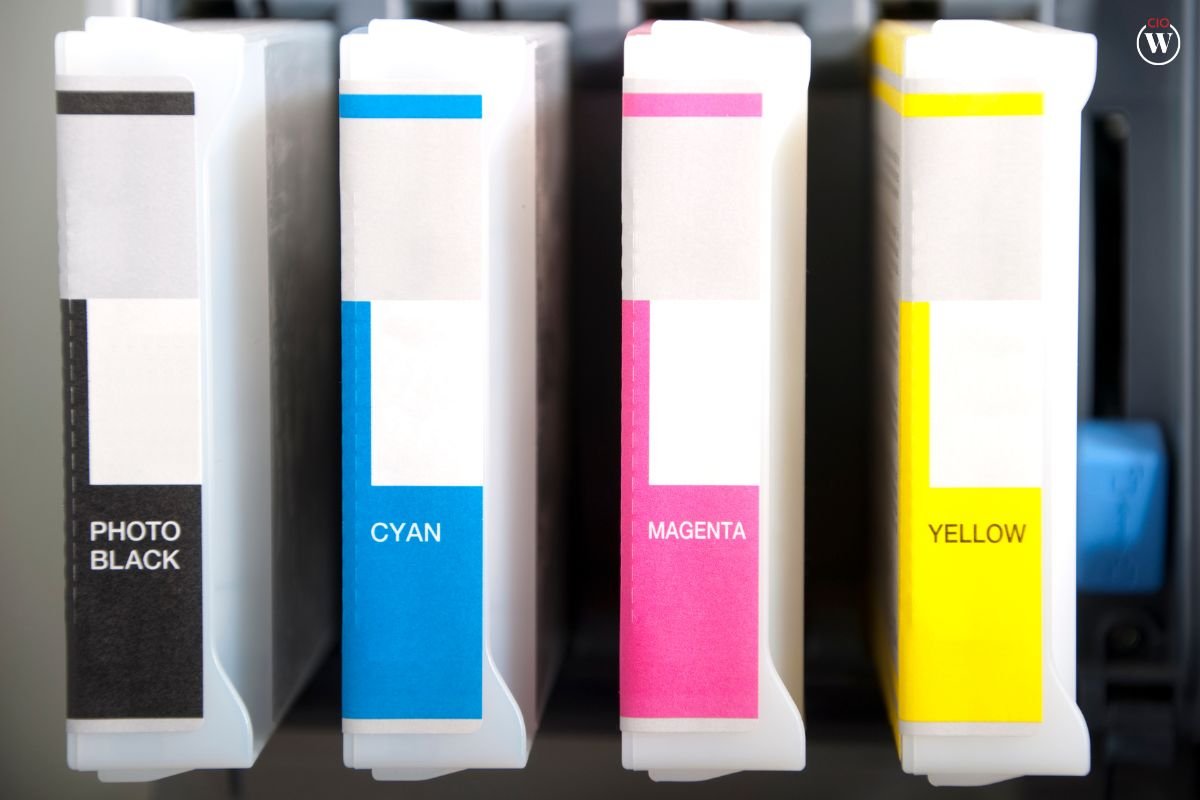

1. Pigment vs. Water-Based Inks

When considering which type of ink best suits your specific needs, you’ll need both an understanding of your preferred method for DTG printing and the intended application of your prints. Pigment inks offer excellent wash fastness and colour durability, making them ideal for materials like cotton, where longevity is a top priority. Water-based inks, on the other hand, are more suitable for lightweight materials like synthetic fibres or material blends.

2. Environmentally-Friendly Options

As sustainability becomes an increasingly essential consideration for businesses, opting for eco-friendly ink formulations is another crucial aspect to bear in mind. Several manufacturers now offer eco-conscious DTG inks free from harmful substances such as heavy metals or ozone-depleting chemicals while maintaining exceptional print quality.

Maintenance and Storage

Maintaining the integrity of your ink supply is a vital aspect of preserving its quality and extending its shelf life. Here are some essential factors to consider:

1. Proper Storage Conditions

Storing your inks correctly can significantly prolong their lifespan. Ensure that you keep them out of direct sunlight and maintain an optimal temperature range according to manufacturer recommendations. Exposure to extreme temperatures can compromise the quality of the inks.

2. Regular Printing

DTG printers usually advise keeping your printer active by regularly printing something. This practice prevents ink from drying out, clogging the printhead, or becoming unusable due to prolonged idle periods.

3. Cleaning & Maintenance

Regularly cleaning your printer’s printhead helps remove any dried residue or debris that may affect print quality over time. Follow manufacturer guidelines on how to perform proper cleaning procedures.

4. Consistency and Reliable Results

Using high-quality inks helps maintain consistency and reliability in DTG printing. Inferior-quality inks may lead to inconsistent, patchy prints, varying colour tones, or even clogged printheads, resulting in decreased print quality and wasted time and resources. On the other hand, using reliable and consistent ink formulations ensures predictable results with every print. Printers can have confidence in the colours they choose and the performance of the ink, knowing that they will consistently achieve the desired outcome.

5. Improved Customer Satisfaction

In any business, customer satisfaction is a top priority. When it comes to DTG printing, using high-quality inks directly impacts customer satisfaction in the case of printed garments or merchandise. Printers can exceed customer expectations and leave a positive impression by delivering prints with vibrant colours, fine details, and long-lasting durability. Satisfied customers are more likely to recommend your services to others and become repeat customers themselves.

Conclusion

The art of DTG printing relies on utilizing advanced printing technology and high-quality inks that meet specific criteria such as colour vibrancy, durability, and accuracy in print reproduction. The choice between pigment or water-based inks depends on factors such as garment material and intended usage. By properly storing and maintaining these premium-grade DTG inks, printers can consistently deliver exceptional prints that exceed customer expectations while ensuring long-lasting durability without compromising sustainability. Mastering the art of DTG printing lies in recognizing the importance of quality inks and embracing them as a critical component of the printing process.