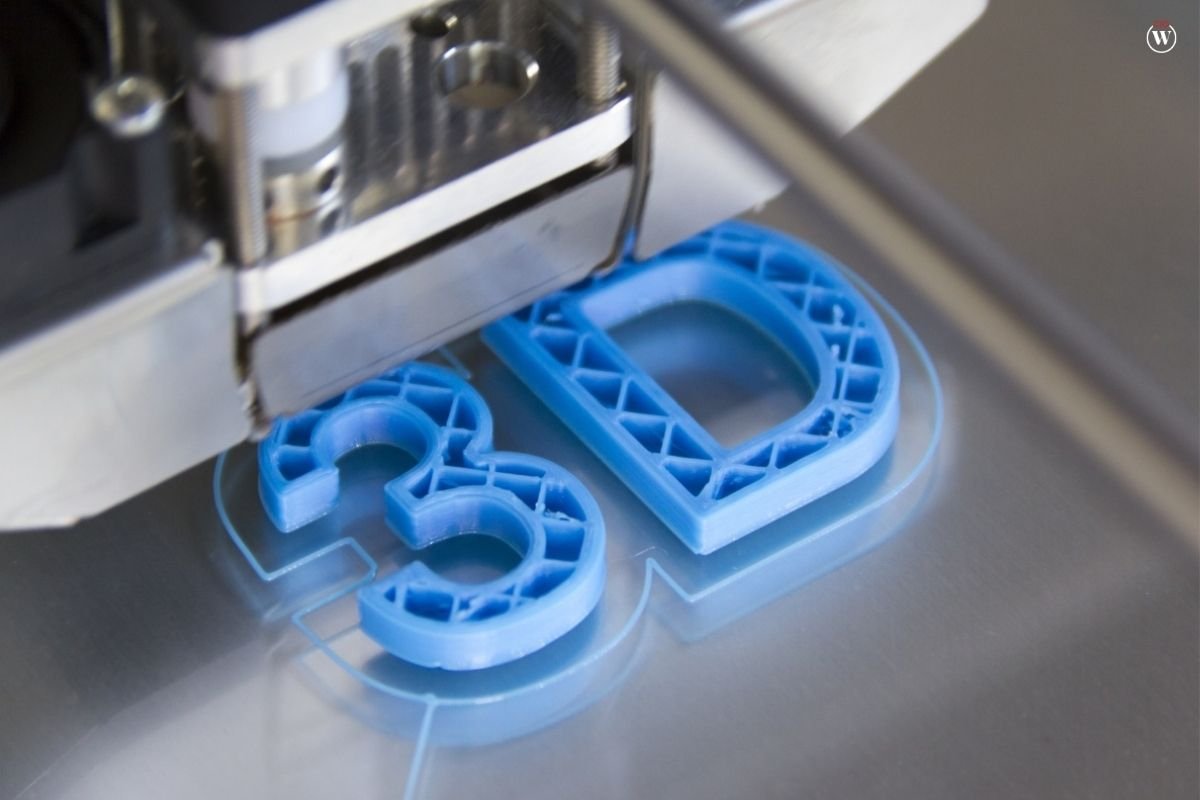

Did you know that 76% of manufacturing firms in the consumer products industry have used 3D printing technology so is this 3d Printing Benefit The Manufacturing Industry? Companies in the consumer goods sector are increasingly investing in 3D printing in order to more efficiently and cheaply meet the needs of their customers. We delve into the advantages of 3D printing and examine how six categories of consumer products are now using the technology.

Listed Below Are 8 Ways in Which 3D Printing Benefit The Manufacturing Industry:

1. Lessening of expenditures

When compared to the traditional manufacturing technique, 3D Printing Benefit The Manufacturing Industry allows for the development of components goods to be made at a lower cost and with more accessibility. With 3D printing, the need for many workers to run a large number of equipment or for a production line to put together the product is eliminated.

In order to begin the automatic process of generating the uploaded design, each 3D printer will need to be started by a human. Since expert machinists and operators aren’t required, the labor expenses associated with 3D printing in production are much cheaper.

2. Safety measures

Confirming a design before committing to production may help reduce the likelihood of mistakes, as well as the costs associated with rework and scrap. Confidence may be boosted while making items using 3D printing and Printing Benefit The Manufacturing Industry, particularly because a 3D prototype is simpler to adapt and change than anything made with more conventional means.

As a result, producers won’t have to make as much of a product to cover the initial investment in equipment and personnel. While fulfilling an order through conventional means generally necessitates a significant number of assembly workers and depends heavily on the efficiency of mass manufacturing, 3D printing often just necessitates filament material.

3. It’s easier and less expensive to fail.

A 3D printer won’t need to be retooled in between manufacturing cycles. One may argue that a 3D printer’s assembly time is longer than that of a conventional production line and Printing Benefit The Manufacturing Industry.

There are many things that may go wrong with traditional manufacturing, such as mechanical difficulties that halt output and human mistakes.

4. Marketing lead-time

With the help of 3D printing, new concepts may be developed rapidly. The design and printing of 3D conceptions may be achievable on the same day in certain cases, but in mass production, 3D printing is unquestionably quicker than traditional techniques. This may help businesses stay ahead of the competition by shortening their production times from months to days.

5. Expand and develop

Businesses that embrace 3D printing may expand and adapt by producing products that were previously only imaginable in their imaginations. With 3D printing, anything can be made in a short amount of time by just designing it digitally and sending the data to a printer Printing Benefit The Manufacturing Industry. As a result, in every industry, a product may go from inception through concept to final form.

6. No Limitations in geometries

For a very long time, conventional production methods have been a hindrance to the development of cutting-edge product designs. The 3D manufacturing process has infinite potential, thanks to the numerous advancements that have been done and will be made in the future.

It is now possible to create shapes that were previously impossible, such as holes with a shift in orientation or inner cavities with a square shape. These layouts are now feasible and easy to build Printing Benefit The Manufacturing Industry.

7. Waste reduction

The high cost of materials is a result of the fact that this is a relatively new technology that is gaining popularity. However, as more options become available, the cost might gradually fall. But the total cost is far less than with conventional procedures. Many resources are lost throughout the production process, especially in more conventional methods. 3D printing for production, on the other hand, has the potential to drastically reduce waste via its more effective use of materials.

In terms of raw materials, a 3D printer will only utilize what is fed into its extruder and ultimately utilized in the final product’s construction.

As opposed to injection molds, blow molds typically need the use of supplementary materials to get the desired result. When compared to conventional manufacturing, 3D printing often results in less waste (such as the support material) & Printing Benefit The Manufacturing Industry when it comes to meeting the requirements of mass production.

8. Less storage space

Parts and items for use or sale are often stored in a company’s facility. Consequently, a lot of room is needed to stock items that may be stored for a long time on a shelf, perhaps even years. There is a significant monetary outlay required. Using 3D printing in production helps keep costs down by cutting down on inventory needs.

With the advent of 3D printing for Printing Benefit The Manufacturing Industry, it is now feasible to produce items on demand. Because of this, we can eliminate surplus manufacturing and save money on storage fees.